Process-Analytic-Cooler

Process-Analytic-Cooler

1) Model GT5.65

- Robust construction for industrial application

- Dust and splash water protected. Degree of protection IP 65

2) Model GT5.SE

- LOW BUDGET gas cooler (IP 20) for cabinet installation

- Made in Germany ![]()

![]()

![]()

Functional description:

The Process-Analytic-Cooler model GT5 is used for the safe cooling of process, sample and flue gases in gas analysis technology. The gas to be measured is reduced reliably to a pre-set temperature/dew point via an industrial heat exchanger that is 1200 mm long (spiral form with additional turbulator) made of stainless steel.

The collected condensate is separated via the Water-Acid-Trap (option).

The Water-Acid-Trap offers an additional protection against condensate breakthrough and dust deposits with the integrated membrane technology of the SUN-Control-Analytik. After the Process-Analytic-Cooler you have a dry and dust-free sample gas corresponding to dew point for your high quality gas analyser/gas sensor at your availability.

The Process-Analytic-Cooler can be used also for cooling of fluids.

Overview of advantages:

- Robust gas cooler in transmitter housing (IP 65) for industrial applications

- Fail-safe pipe heat exchanger made of high-performance stainless steel (1.4571). Suitable for combustible gases

- Service-friendly setup with quick replacement system

- Fitted Water-Trap protection against condensate breakthrough

- Ambient temperature up to +60°C possible (desert design)

- Temperature remote monitoring via built-in temperature sensor (option)

- Ideally suitable from electrochemical sensors/measuring heads to upper class analyzers

Suitable for the following applications:

- Emission measurements with fossil fuels

- Renewable energy (Hydrogen technology)

- Biogas

- Process measurement

- Heat treatments

- Cement, glass-, steel-, paper industries

Not suitable for the following applications:

- Official measurements such as TA-Luft and BImSchV measurements are only possible to a limited extent

- Applications with more than one heat exchanger

Technical data:

| Scope of delivery: | Protective housing inside: Heat exchanger stainless steel, Peltier cooling module, temperature regulator, Temperature indicator, temperature alarm via electrical contact Temperature monitoring via temperature sensor PT100 (option) Heat sink with fan and wall mounting bracket Water-Acid-Trap model WT2048KOBE (option) |

| Degree of protection: | IP 65 alternative IP 20 |

| Power supply: | 24 V/DC, 5,5 A 150 VA. Connecting terminal 0.7-1.5 mm², cable gland M16 |

| Cooling technology: | Peltier, TEC thermoelectric cooler |

| Heat exchanger: | Number 1, volume 20 ml, material stainless steel 1.4571 (HC 22, PTFE on request) |

| Flow rate: | 0 - 250 L/h (0 – 500 L/h on request) |

| Operating pressure: | 0 - 100 bar (higher pressures on request) |

| Differential pressure: | 15 mbar at 250L/h air |

| Gas input temperature: | +5°C - +140°C |

| Input dew point: | 0°C - +70°C |

| Gas output dew point: | Factory setting +8°C (feasible from +5°C to +15°C), dew point stability:+ / - 0,5°C |

| Max. Cooling capacity: | 115 kj/h |

| Ambient temperature: | +5°C - +45°C (+60°C on request) |

| Ready for operation: | 30 minutes |

| Temperature alarm: | Single-pole potential-free contact. Contact load 250 VAC/ 1 A |

|

Temperature monitoring: (Option) |

Via built-in temperature sensors, the current temperature of the Analytic-Cooler can be integrated into a customer SIL loop. SIL 2 preparation via 1 piece 3 wire PT 100 class A, t90 12sec. |

| Temperature display: | Analogue indicator bimetallic |

| Gas connections GT5: | GAS-IN 6 mm pipe nozzle, GAS-OUT 6 mm pipe nozzle |

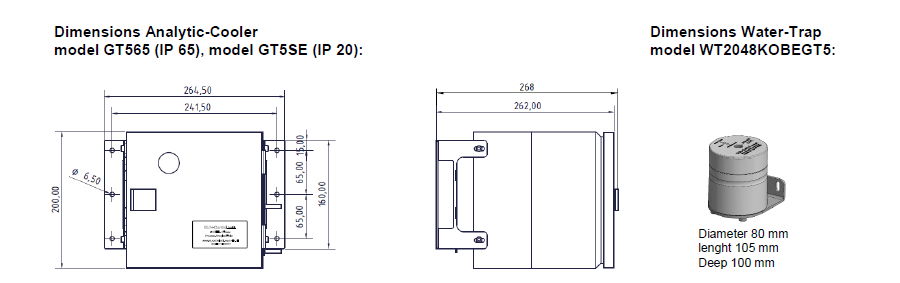

| Dimensions/Weight: | Width 330 mm height 220 mm, depth 270 mm, 12 kg |

| Mounting: | Wall mounting/ plate via mounting bracket (included in scope of delivery) |

| Approval: | UL 508A, Low Voltage Limited Energy Circuits (on request) |

| Assembly: | Wall assembly/assembly plate |

| Note: | The technical data applies at +25°C ambient temperature. In the case of increasing ambient temperature a reduction in performance is to be expected. Water-soluble components, such as e.g. sulphur dioxide (SO2) and nitrogen dioxide (NO2), can be influenced by condensation. |

Schematic diagram:

The Process-Analytic-Cooler drains the condensate via external components, e.g. stainless steel Water-Trap Model WT 20.48 KOBEGT5 (option). This constellation is used in the monitoring of hydrogen and oxygen during electrolysis (see application examples).

Note: Connection (dashed line) from the Analytic-Cooler (GT5) to the Water-Trap (WT2048BOBEGT5) is supplied by the customer (not included in the scope of delivery).

Technical data Water-Trap model WT2048KOBEGT5 (option):

| Scope of delivery: | Housing with integrated cartridge, assembly bracket |

| Water pressure membrane: | 0 - 1 bar |

| Operating pressure for gas: | 0 - 100 bar |

| Diaphragm pore size: | < 0.1 μm |

| Effective filter area: | 550 cm2 |

| Operating temperature: | 0°C - +90°C |

| Housing volume: | 200 ml |

| Materials used: | Stainless steel type 1.4571 (SS316Ti), PTFE, PP, FKM |

| Wall mounting bracket: | Stainless steel type 1.4301 |

| Dimensions: | Diameter 80 mm, length 100 mm, deep 100 mm |

| Gas connections: | GAS-IN 1/4“G-inside thread GAS-OUT 1/4“G-inside thread KONDENSAT-OUT 1/4“G-inside thread |

| Assembly: | Wall mounting with assembly bracket |

| Gas explosion proof ATEX: | Ex II 2G Ex h IIC Gb 0°C ≤ Ta ≤ +90°C |

| Certificates/attestations: | certificate of conformity ATEX 2014/34/EU, Helium leakage test attestation |

| SUNOX100-process Oil and grease-free products for applications with 100% oxygen (on request) |

|

protection of utility patents DE 20 2017 103 071

Article numbers:

| Article | Article number |

|---|---|

| Process-Analytic-Cooler IP 65 model GT5.65 according to technical data | GT565 |

| Process-Analytic-Cooler IP 20 model GT5.SE according to technical data | GT5SE |

| Water-Trap model WT 20.48 KOBE material stainless steel, with stainless steel assembly bracket for wall mounting | WT2048KOBEGT5 |

Options:

| Article | Article number |

|---|---|

| Temperature monitoring via 1 piece temperature sensor PT100 (SIL 2 preparation) | SIL2GT5 |

| Material certificate 3.1 for heat exchanger | MATZGT5 |

Spare parts:

| Article | Article number |

|---|---|

| Air blower IP65 | GEBLGT5 |

| Heat exchanger made of stainless steel 1.4571 with cooling dome | WAETGT5 |

| Temperature regulator | TR2EGT5 |

| Temperature analogue indicator | TAZGT5 |

| Cartridge Water-Acid-Trap | KAWT2048 |

| O-ring for Water-Acid-Trap, FKM (color green) | OR2048FKM |

PreviousPage (no previous) - NextPage (no next) - TOP