Menu

- Startseite

- Produkte

- Produktübersicht

- Modell WT 20.5

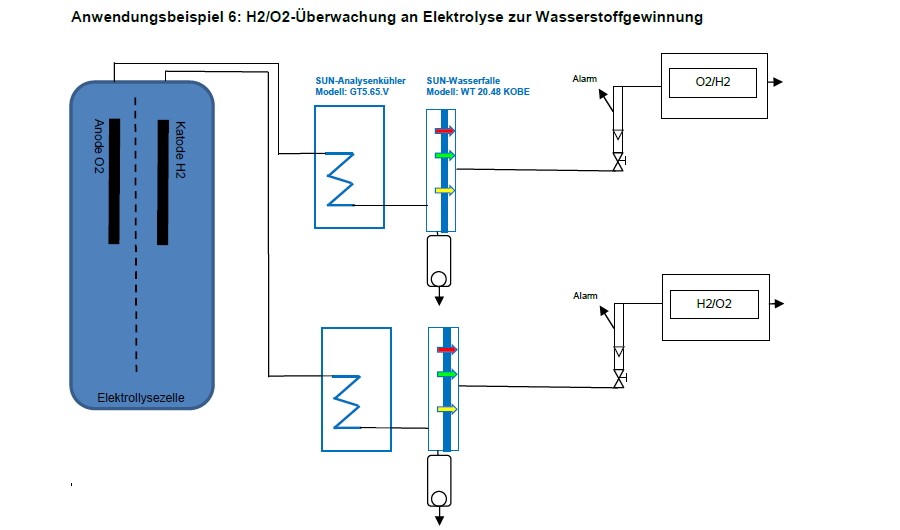

- Modell WT 20.48 KOBE - KOBU

- Modell WT 20.5 A

- Modell WT 20.83 PVDF XL

- Modell WT 20.83 E XL

- Modell WT 20.83 E

- Modell WT 20.83 E XL HD

- Modell WT 20.82 E

- Modell WT 30.5 E

- Modell PC 1410 E

- Modell PC 1410 E XL

- Modell PC 1410 PVDF / EL

- Modell SF 20.13

- Modell PF 20.17

- Modell ABS 20.03

- Modell GEF 26

- Modell KVE

- Modell SPENIV

- Modell GT5 65 / SE

- Modell GT5.EX

- Funktionsprinzip

- Einbaubeispiele

- Kontakt und Ersatzteile

- Download

- Video Funktionsprinzip

- Über uns

- Datenschutz

- Impressum

You are here: Startseite