Process-Analytic-Cooler

Process-Analytic-Cooler

model GT5.EX

- Gas-Explosion proof design for zone 1

- Dust-Explosion proof design for zone 21

- Robust Transmitter design (degree of protection IP 66)

- Low space requirement

- Easy to maintain construction with Quick-Change-System

- Effective industrial heat exchanger with 1200 mm length

- Temperature monitoring with alerting system

- Water-Trap with protective function

- Made in Germany ![]()

![]()

![]()

Unique features:

- Gas and dust explosion proof design (Ex d)

- Temperature class T6

- Degree of protection IP 66 for outdoor installation

- Ambient temperature -20 ° C to + 50 ° C

- No running compressor components

- No motor protection switch necessary

- Temperature remote monitoring via PT100

Functional description:

The Process-Analytic-Cooler model GT5.Ex is used for the safe cooling of process, sample and flue gases in gas analysis technology. The gas to be measured is reduced reliably to a pre-set temperature/dew point via an industrial heat exchanger that is 1200 mm long (spiral form with additional turbulator) made of stainless steel.

The collected condensate is separated via the Water-Trap (option).

The Water-Trap offers an additional protection against condensate breakthrough and dust deposits with the integrated membrane technology of the SUN-Control-Analytik. After the Process-Analytic-Cooler you have a dry and dust-free sample gas corresponding to dew point for your high quality gas analyser/gas sensor at your availability.

The Process-Analytic-Cooler can be used also for cooling of fluids.

Technical data:

| The model GT5.Ex is approved for use in potentially explosive atmospheres of Zones 1 and 21 and comply with the following standards and regulations:IEC/EN 60079-0, 60079-1, 60079-31 |

|

| EPS 17 ATEX 1 072 | |

| Gas: | EX II 2G Ex db IIC T4 Gb (Tamb +60°C) EX II 2G Ex db IIC T6 Gb (Tamb +40°C) |

| Dust: | EX II 2D Ex tb IIIC T130° Db (Tamb +60°C) EX II 2D Ex tb IIIC T80° Db (Tamb +40°C) |

| IECEx EPS 17.0036 | |

| Gas: | Ex db IIC T4 Gb (Tamb +60°C) Ex db IIC T6 Gb (Tamb +40°C) |

| Dust: | Ex tb IIIC T130° Db (Tamb +60°C) Ex tb IIIC T80° Db (Tamb +40°C) |

| The model GT5.Ex.Z2 is approved for use in potentially explosive atmospheres of Zones 2 and 22 and comply with the following standards and regulations:IEC/EN 60079-0, 60079-1, 60079-31 |

|

| EPS 17 ATEX 1 072 | |

| Gas: | Ex II 3G Ex db IIC T4 Gc (Tamb +60°C) Ex II 3G Ex db IIC T6 Gc (Tamb +40°C) |

| Dust: | Ex II 3D Ex tc IIIC T130° Dc (Tamb +60°C) Ex II 3D Ex tc IIIC T80° Dc (Tamb +40°C) |

| IECEx EPS 17.0036 | |

| Gas: | Ex db IIC T4 Gc (Tamb +60°C) Ex db IIC T6 Gc (Tamb +40°C) |

| Dust: | Ex tb IIIC T130° Dc (Tamb +60°C) Ex tb IIIC T80° Dc (Tamb +40°C) |

| Scope of delivery: | Protective housing inside: Heat exchanger stainless steel, Peltier cooling module, temperature regulator,controller Temperature indicator, temperature alarm via electrical contact Temperature monitoring via temperature sensor PT100 (Option) Heat sink with wall mounting bracket Water-Acid-Trap with assembly bracket for wall mounting (option) |

| Degree of protection: | IP 66 (dust protection / water hose-proof) |

| Power supply: |

85 V AC bis 264 V/AC, 150 VA, 24 V/DC Connecting terminal 0.7-1.5 mm², 1 x M20 Ex |

| Cooling technology: | Peltier,TEC thermoelectric cooler |

| Heat exchanger: | Number 1, volume 20 ml, material stainless steel 1.4571 (HC 22 on request) |

| Flow rate: | 0 - 180 L/h (0-500 L/h on request) |

| Operating pressure: | 0 - 12 bar |

| Differential pressure: | 15 mbar at 180 L/h air |

| Gas input temperature: | +5°C - +100°C (+5° C - +150°C on request) |

| Input dew point: | max. +70°C |

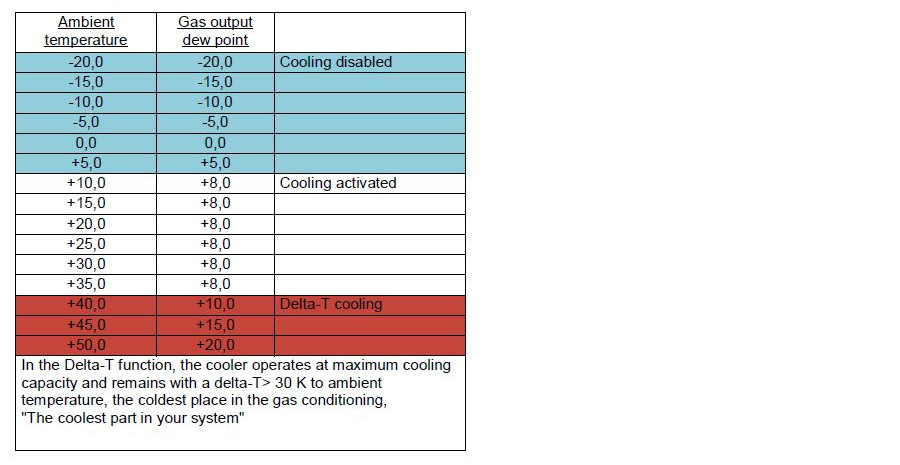

| Gas output dew point: | Factory setting +8°C (feasible from +5°C to +15°C), Dew point stability:+ / - 0,5°C with Delta-T cooling see diagram |

| Max. Cooling capacity: | 94 kj/h |

| Ambient temperature: | -20°C - +50°C (higher ambient temperatures on request) |

| Ready for operation: | 30 minutes |

| Temperature alarm: | Single-pole potential-free contact. Contact load 250 VAC/ 1 A |

| Temperature monitoring: (Option) | Via built-in temperature sensors, the current temperature of the Analytic-Cooler can be integrated into a customer SIL loop. SIL 2 preparation via 1 piece 3 wire PT 100 class A, t90 12sec. |

| Temperature display: | Analogue indicator bimetallic |

| Gas hook up GT5.EX: | GAS-IN 6 mm pipe nozzle, GAS-OUT 6 mm pipe nozzle |

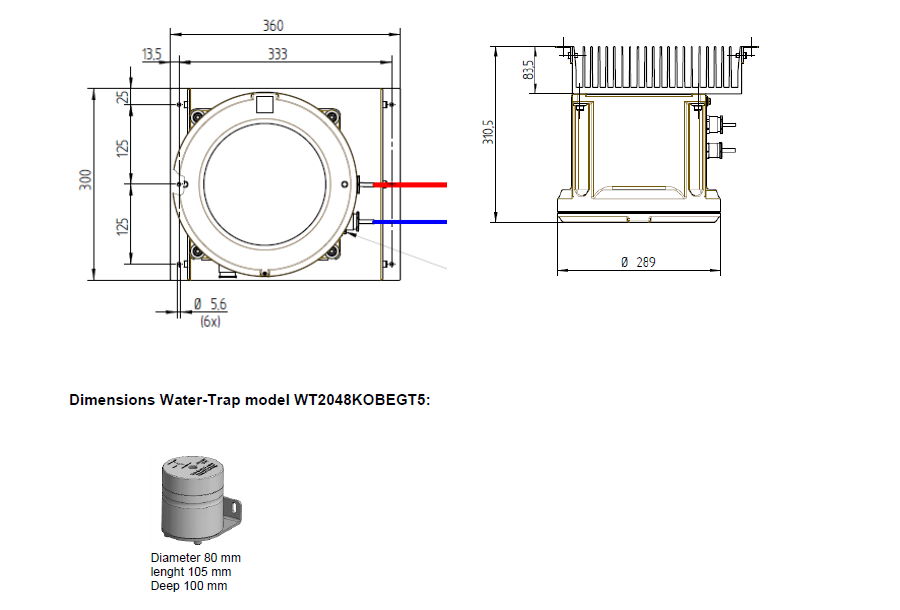

| Dimensions/weight: | Width 360 mm, height 300 mm, depth 320 mm, 28 kg |

| Mounting: | Wall mounting/ plate via mounting bracket (included in scope of delivery) |

| Approval: | UL 508A, Low Voltage Limited Energy Circuits (on request) |

| Note: | The technical data applies at +25°C ambient temperature. In the case of increasing ambient temperature a reduction in performance is to be expected. Water-soluble components, such as e.g. sulphur dioxide (SO2) and nitrogen dioxide (NO2), can be influenced by condensation. |

Gas output dew point:

Schematic diagram:

The Process-Analytic-Cooler drains the condensate via external components, e.g. stainless steel Water-Trap Model WT 20.48 KOBEGT5 (option). This constellation is used in the monitoring of hydrogen and oxygen during electrolysis (see application examples).

Note: Connection (dashed line) from the Analytic-Cooler (GT5) to the Water-Trap (WT2048BOBEGT5) is supplied by the customer (not included in the scope of delivery).

Technical data Water-Trap model WT2048KOBEGT5 (option):

| Scope of delivery: | Housing with integrated cartridge, assembly bracket |

| Water pressure membrane: | 0 - 1 bar |

| Operating pressure for gas: | 0 - 100 bar |

| Diaphragm pore size: | < 0.1 μm |

| Effective filter area: | 550 cm2 |

| Operating temperature: | 0°C - +90°C |

| Housing volume: | 200 ml |

| Materials used: | Stainless steel type 1.4571 (SS316Ti), PTFE, PP, FKM |

| Wall mounting bracket: | Stainless steel type 1.4301 |

| Dimensions: | Diameter 80 mm, length 105 mm, deep 100 mm |

| Gas connections: | GAS-IN 1/4“G-inside thread GAS-OUT 1/4“G-inside thread KONDENSAT-OUT 1/4“G-inside thread |

| SUNOX100-process Oil and grease-free products for applications with 100% oxygen (on request) |

|

protection of utility patents DE 20 2017 103 071

Article numbers:

| Article | Article number |

|---|---|

| Process-Analytic-Cooler, model GT5.Ex, for use in potentially explosive atmospheres of Zones 1 and 21 | GT5EX |

|

Process-Analytic-Cooler, model GT5.Ex.Z2, for use in potentially explosive atmospheres of Zones 2 and 22 |

GT5EXZ2 |

| Water-Trap model WT 20.48 KOBE material stainless steel, with stainless steel assembly bracket for wall mounting | WT2048KOBEGT5 |

| Options: | |

| Temperature monitoring via 1 piece temperature sensor PT100 (SIL 2 preparation) | SIL2GT5 |

| Material certificate 3.1 for heat exchanger | MATZGT5 |

| Spare parts: | |

| Power supply | NTGT5EX |

| Heat exchanger made of stainless steel 1.4571 with cooling dome | WAETGT5EX |

| Temperature regulator | TR2EGT5EX |

| Temperature analogue indicator | TAZGT5 |

| Cartridge Water-Acid-Trap | KAWT2048 |

| O-ring for Water-Trap FKM, colour green | OR2048FKM |

| O-ring for Ex-d housing | ORGEHGT5EX |

Dimensions Process-Analytic-Cooler model GT5.Ex:

PreviousPage Model GT5 65 / SE << - NextPage >> Function principle - TOP